Last Updated on 15.11.2024 by hrushetskyy

Learn how your tire pressure sensors work to make sure you know when your tire pressure drops too low, keeping you safe on the road.

Tire Pressure Sensors 101: The Basics Every Motorist Should Know

Have you ever noticed a light on your dashboard that looks rather like a cauldron with an exclamation point in it? Well, that’s your tire pressure monitoring system warning light (and the cauldron is actually a tire with dangerously low pressure). If you’ve ever wondered how your tire pressure sensors work, read on to learn everything you need to know.

Evolution of the tire pressure monitoring system (TPMS)

Nowadays, you’ll find Tire Pressure Monitoring Systems (TPMS) in pretty much all vehicles, keeping us safe from the risks of underinflated tires. However, you used to only find TPMS sensors in luxury cars, so how did they find their way into every car? The journey of TPMS is quite fascinating, shaped by some key events and important regulations.

Early beginnings

Like many new technologies, TPMS sensors were first only for the rich. When they came out in the 1980s they were only available as an option on luxury cars. These early systems were designed to alert drivers to significant tire pressure changes, to improve driver safety and car performance. Back then, only a few people had these systems in their cars, but the technology was out there. And it only took a tragic controversy for TPMS sensors to become legally required.

Firestone and Ford tire controversy

What pushed TPMS adoption into the news was the notorious Firestone and Ford tire scandal of the late 1990s. Sadly, there were many fatal accidents caused by tire failures on Ford Explorer SUVs equipped with Firestone tires. Many of these accidents were linked to underinflated tires, leading to blowouts, and loss of control by the drivers.

Suddenly, installing a tire pressure monitoring system seemed more important, as it could monitor and alert drivers to any tire pressure issues and even save lives.

TREAD Act and regulatory mandates

In response to the Firestone and Ford controversy, Congress passed the Transportation Recall Enhancement, Accountability, and Documentation (TREAD) Act in 2000. This legislation required all passenger vehicles and light trucks to have TPMS installed, which would warn drivers when their tire pressure dropped by 25% or more from the manufacturer’s recommended level.

Thanks to the TREAD Act, a phased TPMS implementation schedule was put in place. By 2008, all passenger vehicles and light trucks sold in the U.S. had to have TPMS. This means that, nowadays, almost all vehicles, including used cars, will have them installed. This has helped keep countless drivers safe on the roads now that they know when the air pressure in their tires drops too low.

Types of TPMS

If you want to understand your vehicle’s TPMS system, you first have to know which type you have – direct or indirect systems.

Direct TPMS

Direct systems are generally the most common and popular TPMS, so it’s useful to know how they work.

Sensor placement

In Direct TPMS, the tire pressure monitoring sensors are placed directly on each wheel, either strapped around the wheel’s drop center or attached to a special tire valve. This clever placement allows the sensor to measure tire pressure accurately and send the data to the vehicle’s onboard systems.

Measurement and transmission

The direct sensors continuously measure tire pressure and transmit this information via radio waves to the vehicle’s onboard computer. Each sensor includes a built-in, non-replaceable battery, so when the battery runs out, you need a new sensor.

So as not to interfere with other radio signals, direct TPMS systems use specific radio frequencies. In the U.S., many systems use 315 MHz, while European systems often use 433 MHz. Using specific frequencies like this means you won’t have any issues with interference from other vehicle systems.

System components

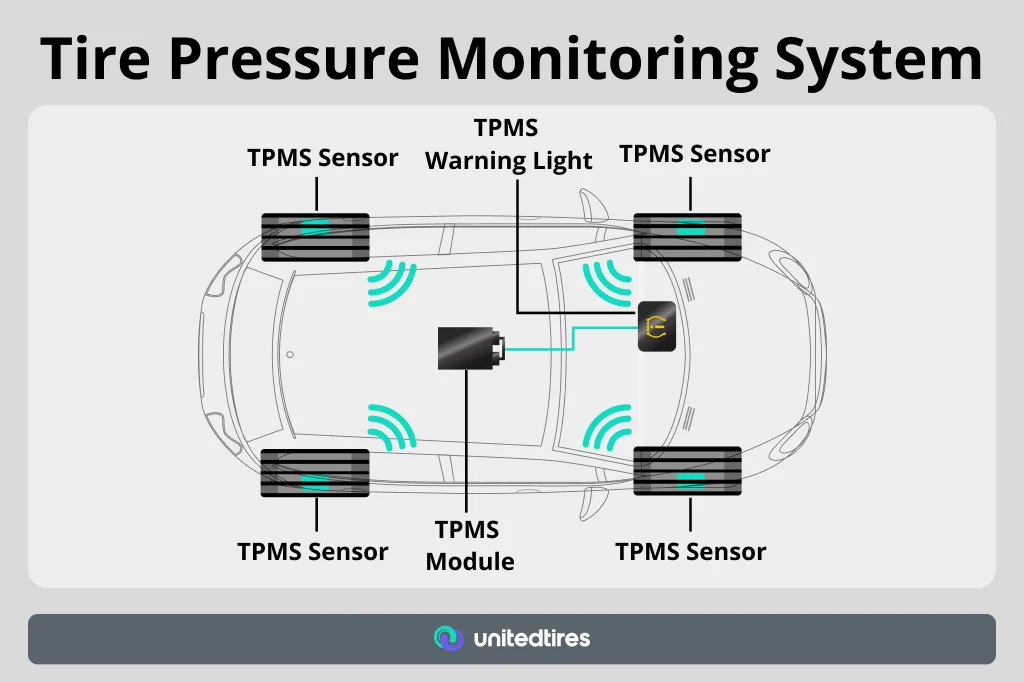

You’ll find that your direct TPMS system will probably have all of these components:

- Tire Pressure Sensor and Air Valve: The tire pressure sensor measures the pressure in your tire directly, and will often also measure the temperature. These sensors will send data to your vehicle’s electronic control unit (ECU). These sensors are either clamp-in or snap-in with a replaceable valve stem.

- Tire Pressure Warning Antenna and Receiver: The antenna and receiver take the signals from the sensors and send them to your tire pressure warning control unit. You’ll quite often find the antenna in the receiver for your remote door lock/unlock receiver, although some cars will have their own, dedicated TPMS sensor receiver.

- Tire Pressure Warning Control Unit: This unit is the brains of the operation. It processes the data it gets from sensors and triggers the TPMS warning light on your dashboard if your tire pressure drops too low.

- Tire Pressure Warning Light and Reset Switch: The TPMS light is how you know you have low tire pressure or system issues. You also have a reset switch that allows the system to relearn sensor data after adjustments, like tire rotation, making sure the system is accurate and reliable.

As you can see, a direct TPMS is an impressive piece of safety technology. It’s always there, continuously monitoring your tire’s air pressure and giving you timely alerts. As well as keeping you safe, it also helps prevent tire failures, improves your fuel efficiency, and can enhance your vehicle’s overall performance.

Indirect tire pressure monitoring systems (TPMS)

The second type of tire pressure monitoring system is the indirect TPMS. It monitors tire pressure uniquely, using some of your existing vehicle components, so let’s find out more.

Wheel speed sensors input

Unlike Direct TPMS, Indirect TPMS doesn’t measure your tire pressure directly. Instead, it uses the wheel-speed sensors from your anti-lock brake system (ABS). These sensors detect each wheel’s rotation speed. When a tire loses air, it shrinks a bit, and this smaller diameter makes it spin faster to cover the same distance as properly inflated tires. This difference in rotational speed is how your Indirect TPMS decides if you have any issues with tire pressures.

Detection mechanism

Indirect TPMS works by constantly checking wheel speed and making calculations based on it:

- Speed Comparison: The system continuously monitors each tire’s rotational speed. If one tire spins faster than the others, it indicates under-inflation.

- ABS Integration: Your ABS uses data from the speed of your rotating tires to measure the tire’s diameter. When one tire’s diameter gets smaller, this shows it has lower pressure, and the ABS detects this variation.

- Data Processing: The Powertrain Control Module (PCM) or a dedicated control unit processes these speed signals to identify discrepancies indicating low tire pressure and sends the details to your vehicle’s onboard computer.

System components

An Indirect TPMS includes several components:

- Wheel-Speed Sensors: Part of the ABS, these sensors measure each tire’s rotation speed and send real-time data to the PCM or ECU.

- Electronic Control Unit (ECU): This mini-computer processes speed data from all four wheels, using algorithms to compare rotational speeds so it can tell if a tire is underinflated.

- Tire Pressure Warning Light: You’ll find this light on the dashboard. It lights up when the ECU detects a tire pressure issue so you can check and correct your tire pressure.

Advantages and drawbacks

So which type of TPMS sensors is it best to have? Indirect TPMS is generally less expensive and easier to maintain than Direct TPMS but has some limitations. It can misinterpret different wheel sizes or fail to detect simultaneous pressure drops in all tires, making it less accurate in some scenarios. Additionally, it requires recalibration after tire rotations or replacements.

Either way, having a well-maintained TPMS will help you avoid the problems that come with a flat tire or total tire failure.

Frequently Asked Questions

How do tire pressure sensors send signal?

Tire pressure sensors send signals using tiny radio transmitters embedded within the tire. These TPMS sensors constantly monitor the air pressure inside the tire, and if it drops too far, they send a radio signal with the pressure data to your vehicle’s onboard computer. This signal typically travels to an antenna somewhere in the vehicle’s body, which then relays the information to the car’s dashboard. Here, a warning light alerts you to check your tire pressure.

How do tire pressure sensors get power?

Tire pressure sensors get their power from tiny, built-in batteries. These batteries are designed to last several years, typically around 5 to 10, depending on usage and environmental conditions. The battery life is similar to a standard tire life, so you shouldn’t need to worry about changing the battery. The sensors are usually located either inside the tire, attached to the wheel, or on the valve stem, continuously monitoring the tire pressure and sending data to your car’s onboard computer. Since the batteries are sealed within the sensors, they aren’t replaceable, so when they eventually run out, the entire TPMS sensor unit needs to be replaced to ensure your tire pressure monitoring system remains functional.

How does TPMS know where each tire is?

Tire Pressure Monitoring Systems (TPMS) can identify the location of each tire using a process called sensor localization. Many modern vehicles use direct TPMS, where each TPMS sensor has a unique ID that the car’s computer recognizes. When you rotate your tires or install new ones, the car’s TPMS relearns the positions either automatically through driving or manually through a reset procedure.

How does a car read a tire pressure sensor?

A car reads a tire pressure sensor through a process that involves radio frequency signals. Each tire pressure sensor, typically mounted inside the tire on the wheel, measures the tire’s pressure and sometimes its temperature. The pressure readings are then sent by a battery-powered transmitter via a radio signal to the car’s onboard computer system. The car has a receiver, usually integrated into the vehicle’s electronics, that picks up these signals and decodes the data. The system then processes this information and if your tire pressure is too low, it turns on a warning light on your dashboard.

Share the Knowledge